Your enquiry cart is currently empty.

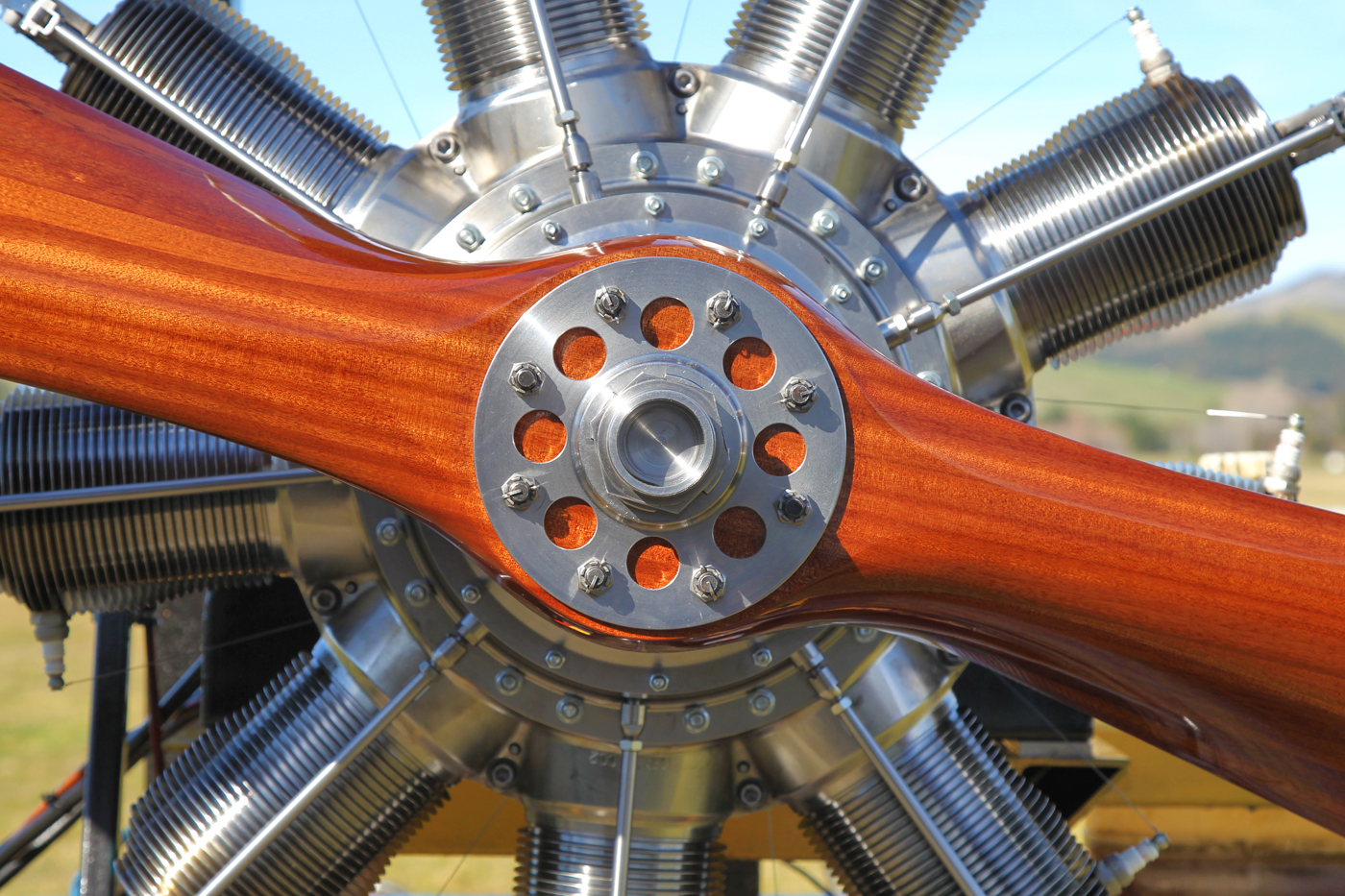

Development/Evolution of the CAMS Gnome 100HP Engine

April 4, 2020

Mosquito relocation

August 28, 2020We have just finished making some P40 Main Retract Tees. The tee fitting screws into the end of the piston rod on the retract cylinder to retract undercarriage. After being told of a cracking issues from a client and after discussions with him lead us to make some small but important modifications before we proceeded. I believe some of the issues were more of a production problem and comes from having to make a lot of parts quickly. At the shoulder at base of the thread there should be a 3/64 corner radius. Of all the original fittings we have seen most would be lucky to have a 1/64 radius, this radius is important as if it’s too sharp then is can lead to stress raisers coming from a sharp corner. If the radius is too large then tee will not bottom on the flange. We were able to increase the radius a little and made sure that it would bottom out on the shoulder of the piston rod. Also in the middle of the thread is a hole which we reduced is size which increases the material on the boss, again adding strength. Tee’s have been made from AISI 4340. NDT, CAD plating and de-embrittlement was done, another great job by the team at Airbus at Woodbourne.