Your enquiry cart is currently empty.

Temporarily Closed

March 25, 2020

P40 Main Retract Tees

July 31, 2020A brief run down of the development/evolution of the CAMS Gnome.

With the lockdown here in NZ I have some spare time to put together an outline of our journey so far.

We have learned a lot along the way but even after eight engines we are still making subtle changes.

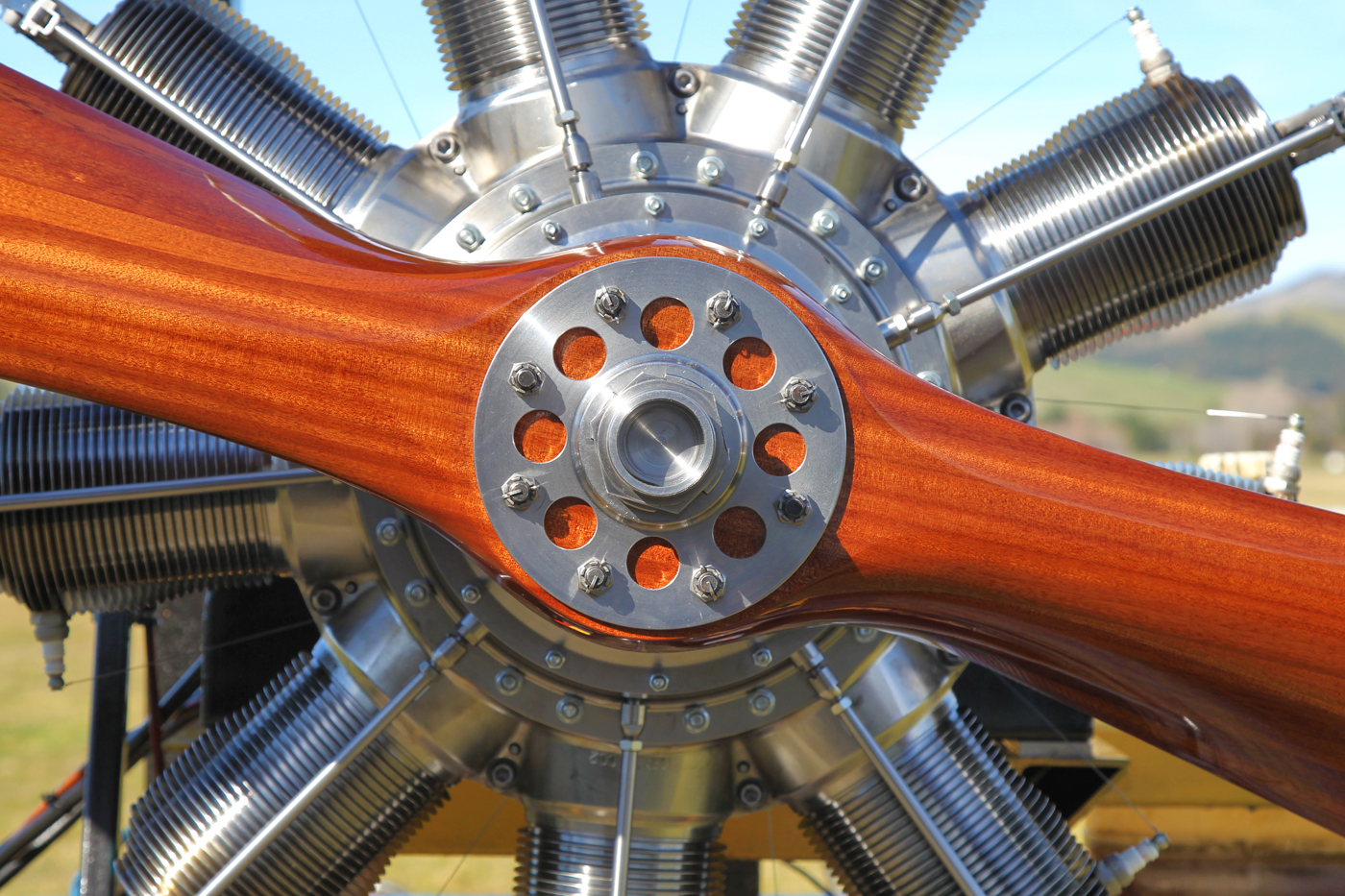

It was eight years ago when we received our first order from Andrew Carter from TAVAS for an engine. That was followed by a second order not long after. We set out to remanufacture the 100 HP Gnome Monosoupape as per the original engine but with the help of some modern technology. We wanted to build a rotary engine that was not only safe and reliable, but was easy to operate. The 100hp Gnome fitted nicely into the easy to operate category but had a reputation (whether true or not) for not being reliable. We made a couple of decisions early on, one was to adapt the engine so we could use “off the shelf” bearings, this was important to help keep costs down. The second was to use forged aluminium pistons. Externally, the engines are the same, which a few years down the track was useful when we did a rebuild of an original engine and were able to use our standard parts to replace unusable original parts.

It was on the 31st January 2014 when #1 Gnome ran for the first time and it was a big day for us all. From there we spent several months testing and tweaking and at the end of it we thought we pretty much had it sorted. Little did we know we had just scratched the surface. We are machinists/engineers not engine designers. In our day to day work we not only machine parts for our cliental but work with them to solve problems. Why it happened… was there another cause…is it made from the wrong material…can we make it better? The same approach has been applied to the engine and we are working to continually improve. We found old school motor re-conditioners good to talk with and we also had the opportunity to talk with engine designer Bill White. I had worked with Bill on a project many years ago and it was good to be able get an outsiders view on what we had already done, and also discuss other ideas on what was possible. Bill had several ideas, and it was great to be able to bounce them around.

Being able to fit an engine on a local aircraft has been a great benefit as the engine runs differently in the aircraft than it does on our test stand. Our engines are able to run at ½ ignition as well as full power, this has proven to be useful for taxiing and also on descent. On the test stand apart from warming the engine up we don’t normally run with the ½ ignition, the engine runs smoother on full power on the test stand. In the aircraft the engine runs smooth both on full and ½ ignition, the engine mount on test stand is too rigid and we need to modify this.

So after eight engines what have we learned.

The old guys were clever bastards, and considering what they had to work with in regards to materials, fuels and oils they did a great job. If you can control air intake then you can control the RPM. Because of the Monosoupape design we can’t control the air coming in through the open valve or maybe we can? After reading about the early Gnome is fitted with variable valve lift to help control engine speed we made a set of cams with a reduced lift on the inlet, and yes, we did get a slight reduction of HP. By controlling the air going through the centre of the crankshaft we found that also it also reduced HP and RPM. What we found is that there needs to be a minimum amount of air going through the centre of the crankshaft to mix with the fuel, this did reduce power but also had issues with spark plugs sooting up and fouling. It also works the other way, we trialled what was essentially a ram air scoop (like the 70’s muscle cars) which created some positive pressure into inlet on the crank. It gave us an increase in power and rpm. What we also found with all of this was by changing the air flow into the crank, we needed to adjust the tampier to get the correct mixture. The Gnome is the easiest of the rotaries to operate and we can control some of the air but we were starting to make it more complicated to operate. This turned out to be a lot of work for little result…back to the KISS principle.

We also did a test in the workshop with the front cam housing. We ran it up at normal engine speed and fed oil into the centre as would happen on start up of an engine. What we found, is it took 20 seconds before the for the oil worked its way through the cam box to the crankcase. Now, if an engine had been sitting for a while, this time could be a lot longer so we felt we needed to do something about this. We came up with a priming pump which primes the main line, and we now supply a hand pump with every engine.

Fuel was one of the things that had a big effect on how the engine ran. We found by reducing the pattern and size of the holes in the fuel nozzle the engine would run better and the plugs were cleaner. The problem is to change the fuel nozzle you have to almost completely strip the engine

to gain access to it. We setup a test and ran an original fuel nozzle, then experimented with other designs and came up with a couple of designs to try. The results were pleasing, the engine was running a lot cleaner, using less fuel and we needed to make less adjustments to the tampier once the engine was running. There seemed a larger range of positions where the engine ran nicely and was easier to operate. A mechanical fuel pump was developed which is based on the pump cast onto the rear of the 160 Gnome, but a little smaller. It fits into the accessory hole on the back plate of the engine and is now fitted as standard to all the engines

It was about then I travelled south to visit Bill White, he seemed to approve of what we had done. We discussed several ideas of possible improvements, he suggested it could be beneficial to machine the inductions holes at the base of the cylinder at an angle. As the rich mixture from the

crankcase enters the cylinder it would direct the air/fuel mix on an angle and start a swirling motion inside the cylinder. Seemed like a good idea so we machined up a set of cylinders with the induction holes offset. While we were at it, we removed some induction holes on the thrust side of the cylinder to help retain oil.

Another idea that came out of the visit (it had also been discussed before) was to fit the pistons with oil control rings, the idea being the ring would wipe oil back down onto the skirt of the piston and would help with lubrication. With the swirling induction and the improved fuel nozzle our next engine ran really nicely and there was a 5 HP gain over the previous engines.

Where to from here?

Have just done a redesign of our ignition system. We have started using an alternator and manufacturing a new front end to mount onto the back plate. It also allows us to mount the hall sensors and the electronic ignition module. This helps with operating the engine making it easier to

manage, it will also charge a battery which for those having the electric start is very useful. This has been designed so we can fit a second ignition module with the view to offering a twin ignition engine.

Looking into trying other types of oil has to be on the agenda, castor is a good oil, but oil has come a long way in 100 years I and am sure there are

other options. The oil control rings in the pistons seem to be doing their job and not only can we look at other oils but also look to reduce the amount of oil the engine needs. We will continue to look for improvements on the CAMS Gnome and also support engines already in service. As serviceable parts for other rotaries become harder to find, then we may look at remanufacturing of other parts and possible rebuilding. We would like to change people’s perception of rotary engines, that they are not dangerous or difficult to operate.