Your enquiry cart is currently empty.

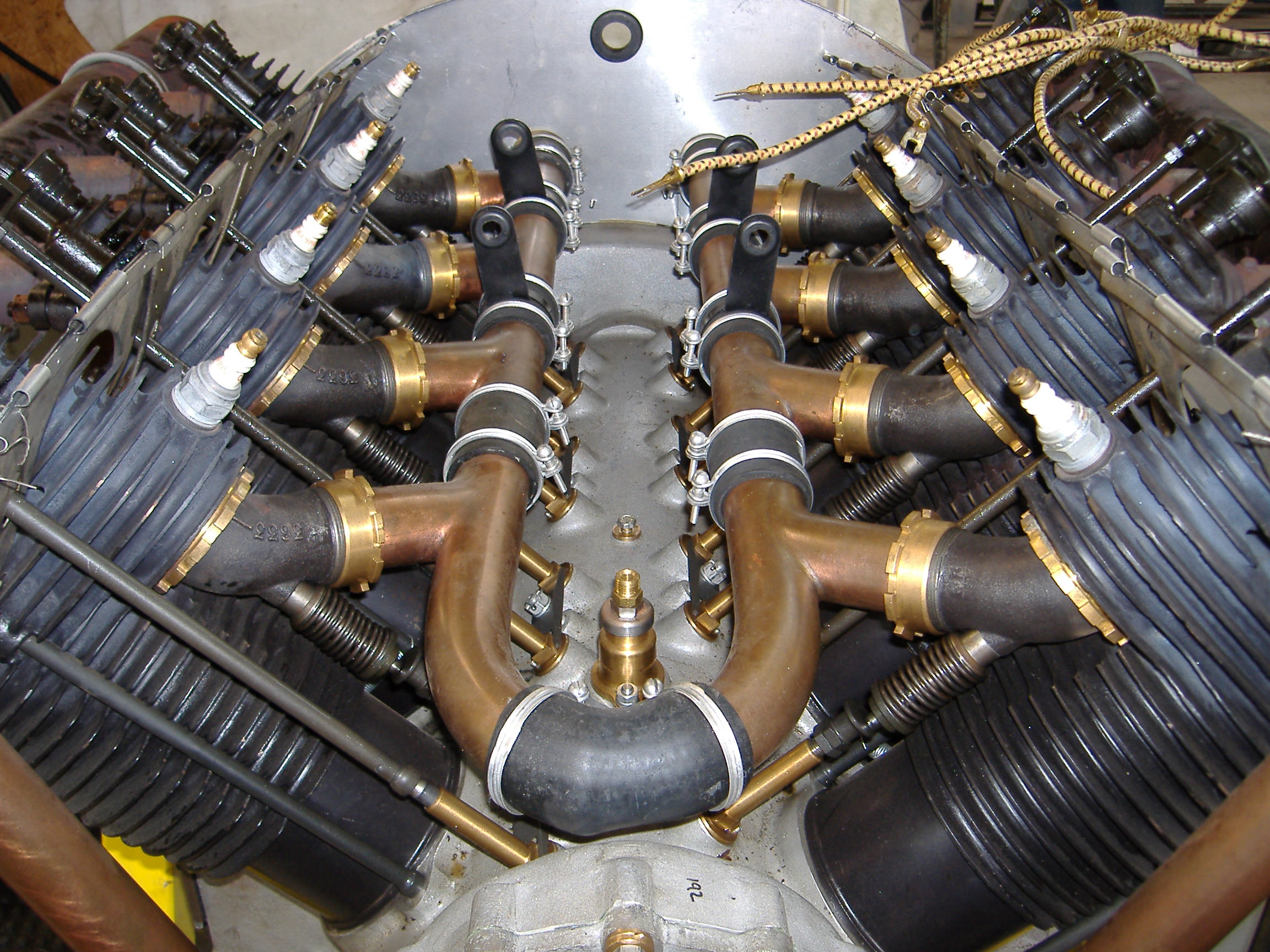

RAF1 Engine

June 30, 2015

P40 Undercarriage Hydraulic Hand Pump

June 30, 2015When parts are fitted, classic or modern, they arrive from the manufacturer set out with pilot holes. When the new part is fitted into the receiving part the final rivet holes are drilled out using a hand held drill. While the final hole should exactly follow the pilot hole, for various reasons that is not always the case.

Not only can CAMS replicate original parts they can match the original holes from the original fitting onto the new fitting. Once the new fitting is made it is setup along with the original in a special jig that allows exact replication of the original hole and drill angle. CAMS have applied this special process to Lockheed 12 wing spars (about 400 holes), Lockheed 10 and 12 main spar/undercarriage fittings and P3 Orion parts.

“That’s the level of attention to detail that we are able to provide.” says CAMS owner Tony Wytenburg. “It’s tedious and quite expensive, but for some owners, the perfection and additional structural integrity achieved is worth the extra cost.”

Derek Johnson of Central Planes Warbirds LLC commented on the match drilled parts: “Our reputation is based on honest work practices and a high quality product regardless of the challenges. We were delighted therefore to find a company in CAMS that has the same attention to detail as we do overcoming the significant challenge of match drilling the Lockheed parts for us. They really do live up to their claims of total attention to detail.” Derek Johnson

www.centralplaneswarbirds.com.